Industry news

What is the difference between COB small spacing and conventional LED small spacing displays?

Conventional LED small-pitch displays use LED lamp beads directly attached to the PCB board. The spacing between the lamp beads is very small. So what is COB small-pitch display?

Generally speaking, LED integrated light sources use COFB packaging technology to directly package LED chips on a vapor chamber or copper substrate to form a multi-crystal array, while COB light sources are high-power integrated surface light sources that directly attach LED luminous chips. Integrated surface light source technology on a highly reflective mirror metal substrate.

The cob light source encapsulates a low-power chip on a PCB board. Compared with ordinary SMD low-power, it has higher brightness, smaller thermal resistance, faster heat dissipation, smaller light attenuation, and longer life.

Although some SMD low-power light sources packaged into aluminum substrates are also called integrated LEDs, they are not COB light sources. So in general, COB light sources are integrated LED light sources, but integrated LED light sources are not all COB light sources.

The COB small-pitch LED display is relatively advanced in terms of technical principles. It has many advantages over conventional small-pitch LED displays, which are mainly reflected in the following:

1. The cob display screen has fewer manufacturing steps and is not as complicated as the SMD packaged LED display screen (LED display screen). There is no patch, reflow soldering and other processes, and the reliability is stronger;

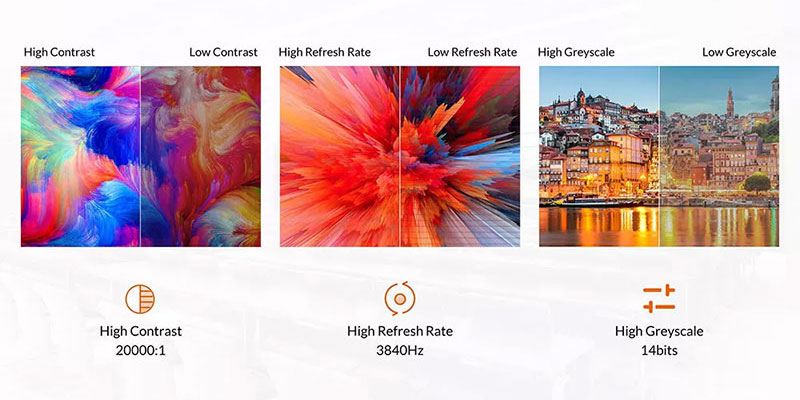

2. Smaller pitch and more delicate picture: COB display screen breaks through the physical limits of SMD packaging process and achieves smaller pitch. With small pitch, more pixels are displayed per unit, the picture is fuller and the colors are more vivid;

3. The cob-encapsulated LED display completely seals the device on the PCB board. The device is not exposed and has a stronger protection level. There is no light loss when directly touched by hand, shaken or during transportation. After the product is put into use, the maintenance rate is almost 0;

4. Surface light source emits light. Effectively suppresses moiré patterns, allowing people to watch at close range for a long time without hurting the eyes;

5. Faster heat dissipation and longer life: heat is dissipated directly through the PCB board, with small thermal resistance and better heat dissipation. Without heat accumulation, the life of electronic products will naturally be longer;

The development of any good thing goes through stages. Although the COB small-pitch LED display is good, it is still an early-stage product and is not very mature in many technologies. For example, the current COB small-pitch LED display is ink-colored on the entire screen. This is a very big problem, and conventional small-pitch LED displays do not have such a problem.

Conventional small-pitch LED displays and COM small-pitch LED displays have certain advantages in terms of price, and the process is relatively less complicated. Moreover, conventional small-pitch LED displays are relatively simple to maintain.

Through the comparison of the above product differences, how to choose depends on whether the customer's priorities are the same. If COB's current disadvantages can be ignored, then it is still a very good product.